- Products

- EQUIPMENT & Accessories

- Plaster Traps

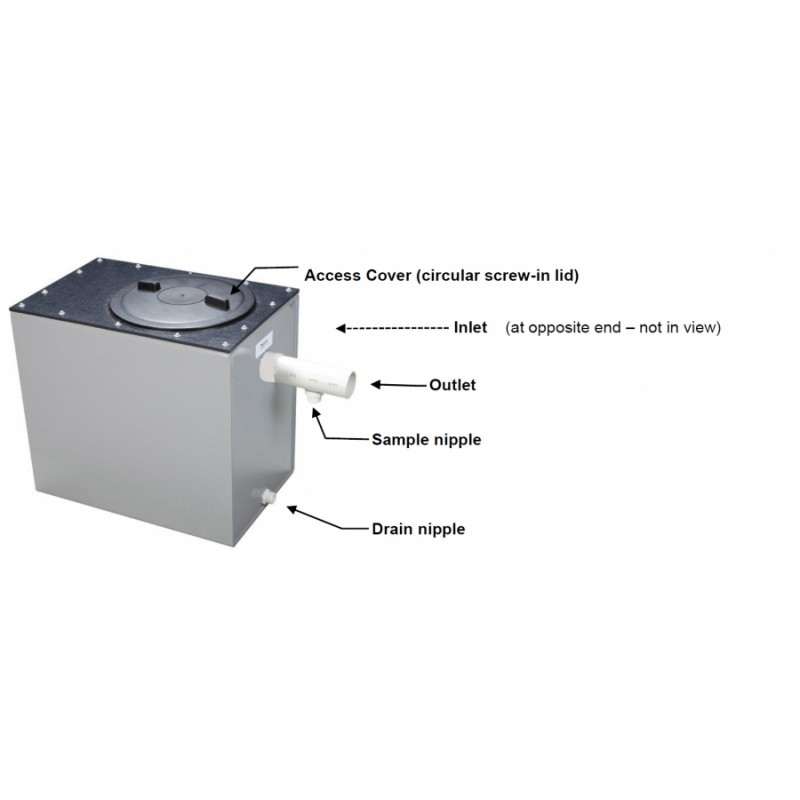

- Plaster Trap (Settling Tank) 72L PVC With Air Tight Lid (Baffled Tank) - Australian Made

Plaster Trap (Settling Tank) 72L PVC With Air Tight Lid (Baffled Tank) - Australian Made

- Product Code: PT-P72

Plaster Trap (Settling Tank) 72L PVC With Air Tight Lid (Baffled Tank) - Australian Made

* To be installed by a licenced plumber

- Australian Made ‐ 6mm PVC

- Australian Standards

- Bafffle System - Manual Empty

- Supplied With:

- Removable Airtight Cover

- Drain Valve Nipple

- Sampling Valve Nipple

- Fixed Baffle At Outlet End

- Settlement Depth 300mm

- External Dimensions Size: 450H x 600W x 400D

INSTALLATION GUIDE AND INFORMATION - DOWNLOAD

INSTALLATION: It is highly recommended to use a licensed plumber to install your plaster trap to ensure it meets current wastewater regulations.

This tank slows the flow of water allowing plaster, clay and other fine (heavier than water) material to sink to the bottom and cleaner water to flow out to sewer.

The PVC Plaster Trap is manufactured to meet all specifications provided by Melbourne Water and South East Water Victoria.

Plumbing Connections:

Settling Tanks 50lt – 200lt (Above-Ground)

50mm Inlet / 65mm Outlet / 25mm BSP Drain & Sample nipples

- Ensure tank will fit in space provided.

- Ensure there is sufficient room above the tank to allow removal of the screw-in Access Cover and for cleaning of the tank (see below) - (tank can be removed entirely for cleaning, in which case pipe connections will have to be disconnectable types such as barrel unions or rubber sleeve connectors).

- Connect sink waste outlet directly into the tank Inlet nozzle.

- Connect tank Outlet to waste in accordance with plumbing regulations (note: Sample nipple is to face down)

- Fit a stop valve to the Drain nipple located at bottom of tank (valve not supplied).

- Fit a stop valve to the Sample nipple located on tank outlet pipe tail (valve not supplied).

Cleaning Guidelines:

The Settling Tank should be maintained regularly to ensure trouble-free service. The tank is designed to arrest waste product such as waterborne clay and plaster particles in order to prevent blockage of downstream drainage pipes. Collected waste product, formed as sludge on the floor of the tank, should be removed from the tank and disposed of by whatever means is allowed in the area. The waste product would not normally be regarded as hazardous and may be suitable for disposal in a general waste collection bin, however, the waste product and liquid contained in the tank is the product of whatever has been fed to the tank and we recommend this point be considered before accessing the tank at all.

- Cleaning of the tank should be performed by a competent person

- Wear appropriate PPE (gloves, safety glasses, breathing mask, etc.)

- Unscrew removable Access Cover

- Open drain valve to allow liquid waste to empty (into bucket for correct disposal)

- Remove sludge waste from the tank and, if necessary, use a small spade or scoop to assist

- Wash the interior tank walls with a trigger hose fitted with a spray nozzle

- Replace access cover and ensure drain valve is closed

- Improved access may be gained by removing the tank from its installed location. Before removing the tank, give some thought to the weight of the tank when full of water or waste product. (A standard 72lt tank will weigh approximately 80KG).

- Wheeled trolleys are also available to assist in removal of a full tank (Optional accessory).

- We recommend the tank be drained or syphoned out in order to reduce the weight before attempting to move it.

- When re-installing the tank, make sure all connections are tight and that valves are fitted and closed before re-filling.

- Test all plumbing connections and the water-tight integrity of the tank after re-filling.

CAUTION:

DO NOT leave PVC tank in temperatures above 50 degrees Celsius.

DO NOT DROP as PVC can be brittle.

Plaster Trap (Settling Tank) 72L PVC With Air Tight Lid (Baffled Tank) - Australian Made

- Product Code: PT-P72

Plaster Trap (Settling Tank) 72L PVC With Air Tight Lid (Baffled Tank) - Australian Made

* To be installed by a licenced plumber

- Australian Made ‐ 6mm PVC

- Australian Standards

- Bafffle System - Manual Empty

- Supplied With:

- Removable Airtight Cover

- Drain Valve Nipple

- Sampling Valve Nipple

- Fixed Baffle At Outlet End

- Settlement Depth 300mm

- External Dimensions Size: 450H x 600W x 400D

INSTALLATION GUIDE AND INFORMATION - DOWNLOAD

INSTALLATION: It is highly recommended to use a licensed plumber to install your plaster trap to ensure it meets current wastewater regulations.

This tank slows the flow of water allowing plaster, clay and other fine (heavier than water) material to sink to the bottom and cleaner water to flow out to sewer.

The PVC Plaster Trap is manufactured to meet all specifications provided by Melbourne Water and South East Water Victoria.

Plumbing Connections:

Settling Tanks 50lt – 200lt (Above-Ground)

50mm Inlet / 65mm Outlet / 25mm BSP Drain & Sample nipples

- Ensure tank will fit in space provided.

- Ensure there is sufficient room above the tank to allow removal of the screw-in Access Cover and for cleaning of the tank (see below) - (tank can be removed entirely for cleaning, in which case pipe connections will have to be disconnectable types such as barrel unions or rubber sleeve connectors).

- Connect sink waste outlet directly into the tank Inlet nozzle.

- Connect tank Outlet to waste in accordance with plumbing regulations (note: Sample nipple is to face down)

- Fit a stop valve to the Drain nipple located at bottom of tank (valve not supplied).

- Fit a stop valve to the Sample nipple located on tank outlet pipe tail (valve not supplied).

Cleaning Guidelines:

The Settling Tank should be maintained regularly to ensure trouble-free service. The tank is designed to arrest waste product such as waterborne clay and plaster particles in order to prevent blockage of downstream drainage pipes. Collected waste product, formed as sludge on the floor of the tank, should be removed from the tank and disposed of by whatever means is allowed in the area. The waste product would not normally be regarded as hazardous and may be suitable for disposal in a general waste collection bin, however, the waste product and liquid contained in the tank is the product of whatever has been fed to the tank and we recommend this point be considered before accessing the tank at all.

- Cleaning of the tank should be performed by a competent person

- Wear appropriate PPE (gloves, safety glasses, breathing mask, etc.)

- Unscrew removable Access Cover

- Open drain valve to allow liquid waste to empty (into bucket for correct disposal)

- Remove sludge waste from the tank and, if necessary, use a small spade or scoop to assist

- Wash the interior tank walls with a trigger hose fitted with a spray nozzle

- Replace access cover and ensure drain valve is closed

- Improved access may be gained by removing the tank from its installed location. Before removing the tank, give some thought to the weight of the tank when full of water or waste product. (A standard 72lt tank will weigh approximately 80KG).

- Wheeled trolleys are also available to assist in removal of a full tank (Optional accessory).

- We recommend the tank be drained or syphoned out in order to reduce the weight before attempting to move it.

- When re-installing the tank, make sure all connections are tight and that valves are fitted and closed before re-filling.

- Test all plumbing connections and the water-tight integrity of the tank after re-filling.

CAUTION:

DO NOT leave PVC tank in temperatures above 50 degrees Celsius.

DO NOT DROP as PVC can be brittle.

Related Products

Plaster Trap (Settling Tank) 37 Litre PVC - Round with Sealed Lid and Internal Grit Basket - Australian Made

Plaster Trap (Settling Tank) 37 Litre PVC – Round with Sealed Lid and Internal Gr..

Plaster Trap (Settling Tank) 22 Litre PVC - Round with Sealed Lid and Internal Grit Basket - Australian Made

Plaster Trap (Settling Tank) 22 Litre PVC – Round with Sealed Lid and Internal Grit Baske..

Plaster Trap (Settling Tank) 12 Litre PVC - Round with Sealed Lid and Internal Grit Basket - Australian Made

Plaster Trap (Settling Tank) 12 Litre PVC - Round with Grit Basket and Sealed Lid - Australian Made ..

-228x228.jpg)