- Products

- 3D Printing Consumables

- 3D PRINTING RESINS - DLP AND MSLA FORMULAS

- DLP 3D Printer Resins (eg. Asiga etc)

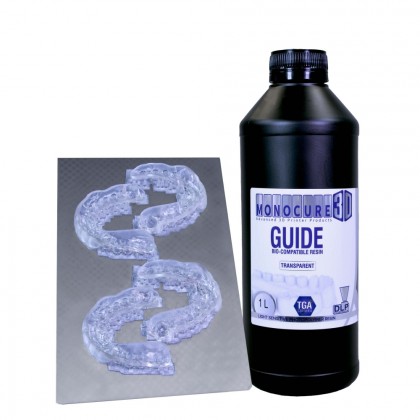

- Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Dental Resin - TRANSPARENT - 1L - Australian Made - INI File Supported for your printer ** DLP Formula Resin ** - SPECIAL ORDER ITEM

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Dental Resin - TRANSPARENT - 1L - Australian Made - INI File Supported for your printer ** DLP Formula Resin ** - SPECIAL ORDER ITEM

- Brand: Monocure 3D

- Product Code: M3D-GB-DLP-1

Australian Made - INI File Supported for your printer ***

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible)

Monocure 3D GUIDE™ bio-compatible dental 3D resin has been engineered to fabricate surgical guides. Once post-cured, this material has high tensile strength and is transparent, odourless and tasteless. It has a high heat resistance and is suitable for sterilisation using standard autoclave protocols.

Monocure 3D’s Surgical GUIDE™ is transparent biocompatible registered Class I material. Our Chemists developed it for high-precision implant-guided surgeries. The high-resolution, rapid layer speed and exceptional mechanical properties provide the ultimate implant assistance.

This resin is available in two formulas for MSLA and DLP 3D printers. It can print within a wide range of UV, between 365 and 405nm.

ARTG No. 398012

THE 3D PRINTED SURGICAL GUIDE

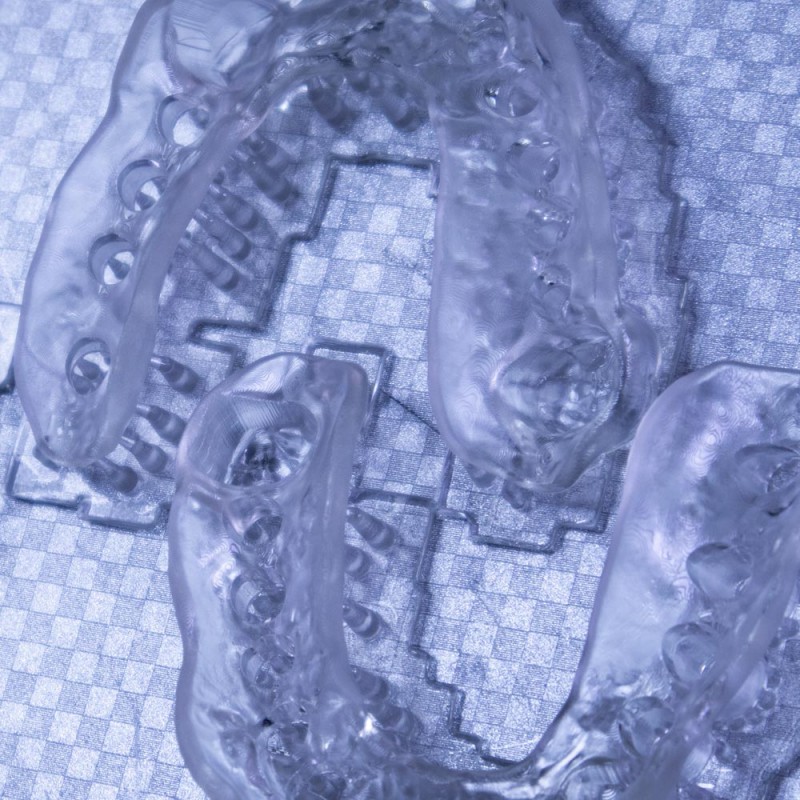

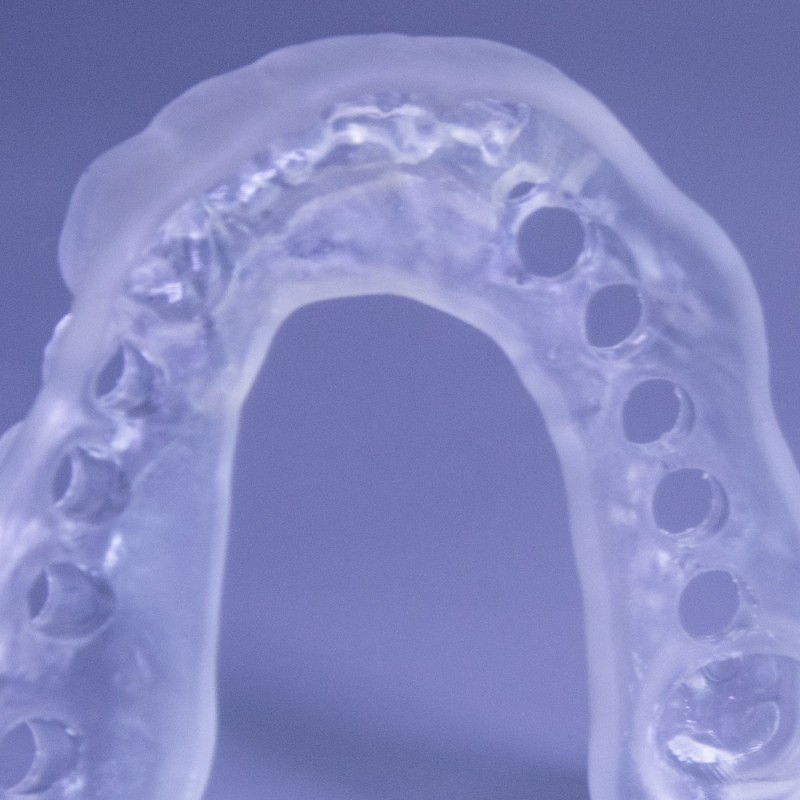

A 3D printed surgical guide reproduces the precise surface of a patient’s intraoral environment and helps the surgeon implant it into the bone with optimum precision. Dental Implant Surgery Guides are used for positioning the dental implants; this is done to ensure that the implants are placed at their ideal position, angle, and depth into the bone.

Although traditional surgical guides will permit guided placement of implants, they will not allow for precise 3D orientation. When conventionally manufactured surgical guides are used, clinical outcomes are generally unpredictable. Even when implants are placed correctly, implant location and misalignment might fail to achieve the best orthodontic requirements.

Preoperative planning using surgical guides can guarantee implant placement safety and decrease the likelihood of complications, an important benefit to younger, less experienced surgeons, making the surgery easier on them. Therefore, it is the responsibility of clinicians to choose among available options of surgical guides for dental implants according to their demonstrated success in contributing to a predictable and precise dental implant placement, how they will be used within the setting of a patient’s oral anatomical environment and the types and degree of guidance that they offer.

A dentist can send scans, get digitally determined optimal placement for implants, and get your implants placed into the exact locations needed for the patients’ restorations you have in mind.

THE GUIDE™ RESIN ADVANTAGE

High Precision

The high accuracy of this material allows for easy-to-insert drill sleeves, realises glue channels, positioning windows, and drill holes.

BIO Compatible

Registered Class I material TGA. It is transparent, odourless and tasteless once cleaned and post-cured.

Autoclavable

Once cured, this material is suitable for sterilisation using standard autoclave protocols. The mechanical properties provide the ultimate implant assistance.

WHICH GUIDE™ FORMULA SUITS YOUR 3D PRINTER?

GUIDE™ BIO Dental Resin is available in two formulas. Since DLP printers output more power than MSLA, we have a version to cover both system types.

Choose the DLP formula if your printer uses a projector module (DLP) to expose the layers. These include brands and models such as the MoonRay, SprintRay, Peopoly Moai, Asiga UV-Max & Pro 4K, Phrozen Make, B9 Creator, Flashforge Hunter, XYZ Nobel, and Kudo Titan.

If your 3D printer uses an LCD screen and a LED array (MSLA) to expose the layers, you must use our regular MSLA formula. These include Anycubic, Phrozen, Creality, Elegoo, Epax, Peopoly, Prusa, Uniz, Wanhao, WOW SparkMaker & Kelant.

ABOUT GUIDE™ BIO DENTAL RESIN

Monocure 3D GUIDE™ bio-compatible dental 3D resin has been engineered to fabricate surgical guides. Once post-cured, this material has high tensile strength and is transparent, odourless and tasteless. It has a high heat resistance and is suitable for sterilisation using standard autoclave protocols.

Monocure 3D’s Surgical GUIDE™ is transparent biocompatible registered Class I material. Our Chemists developed it for high-precision implant-guided surgeries. The high-resolution, rapid layer speed and exceptional mechanical properties provide the ultimate implant assistance.

This resin is available in two formulas for MSLA and DLP 3D printers. It can print within a wide range of UV, between 365 and 405nm.

GUIDE™ - PHYSICAL PROPERTIES (MSLA)

SKUs

M/BIOM-3990C

Colour(s)

Transparent

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1.5-3 seconds per layer (Monochrome LCD)

Storage

Dark, cool & dry place

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible MSLA Printers

- Anycubic

- Phrozen

- Creality

- Elegoo

- Epax

- Peopoly

- Prusa

- Uniz

- Wanhao

- WOW SparkMaker

- Kelant

- Not Listed – Contact Us

GUIDE™ - PHYSICAL PROPERTIES (DLP)

Product Code(s)

M/BIOD-3990C

Colour(s)

Transparent

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1-3 seconds per layer

Storage

Dark, cool & dry place.

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible Printers

- Asiga

- SprintRay

- Peopoly

- MoonRay

- Phrozen Make

- B9 Creator

- Flashforge Hunter

- XYZ Nobel

- Kudo Titan

- Not Listed – Contact Us

Monocure 3D

Australian Made

LOCALLY MADE PRODUCTS EQUALS LOCAL SUPPORT. THE AUSSIE 3D PRINTING BRAND WITH OVER 30 YEARS OF MANUFACTURING EXPERIENCE.

Monocure 3D is at the forefront of Australia’s Dental 3D Printer Resin industry. We are the local leaders of UV technology with more than 35 years of product development and manufacturing experience. The team at Monocure 3D have been working closely with Dental Labs locally and abroad to develop the ultimate Dental 3D Printer Resin.

All our resins are manufactured in Australia using the highest quality materials, following strict ISO 9001 guidelines. Our QC chemists test every batch as we know how important consistency is. Since we manufacture locally, you can say goodbye to supply chain problems.

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Dental Resin - TRANSPARENT - 1L - Australian Made - INI File Supported for your printer ** DLP Formula Resin ** - SPECIAL ORDER ITEM

- Brand: Monocure 3D

- Product Code: M3D-GB-DLP-1

Australian Made - INI File Supported for your printer ***

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible)

Monocure 3D GUIDE™ bio-compatible dental 3D resin has been engineered to fabricate surgical guides. Once post-cured, this material has high tensile strength and is transparent, odourless and tasteless. It has a high heat resistance and is suitable for sterilisation using standard autoclave protocols.

Monocure 3D’s Surgical GUIDE™ is transparent biocompatible registered Class I material. Our Chemists developed it for high-precision implant-guided surgeries. The high-resolution, rapid layer speed and exceptional mechanical properties provide the ultimate implant assistance.

This resin is available in two formulas for MSLA and DLP 3D printers. It can print within a wide range of UV, between 365 and 405nm.

ARTG No. 398012

THE 3D PRINTED SURGICAL GUIDE

A 3D printed surgical guide reproduces the precise surface of a patient’s intraoral environment and helps the surgeon implant it into the bone with optimum precision. Dental Implant Surgery Guides are used for positioning the dental implants; this is done to ensure that the implants are placed at their ideal position, angle, and depth into the bone.

Although traditional surgical guides will permit guided placement of implants, they will not allow for precise 3D orientation. When conventionally manufactured surgical guides are used, clinical outcomes are generally unpredictable. Even when implants are placed correctly, implant location and misalignment might fail to achieve the best orthodontic requirements.

Preoperative planning using surgical guides can guarantee implant placement safety and decrease the likelihood of complications, an important benefit to younger, less experienced surgeons, making the surgery easier on them. Therefore, it is the responsibility of clinicians to choose among available options of surgical guides for dental implants according to their demonstrated success in contributing to a predictable and precise dental implant placement, how they will be used within the setting of a patient’s oral anatomical environment and the types and degree of guidance that they offer.

A dentist can send scans, get digitally determined optimal placement for implants, and get your implants placed into the exact locations needed for the patients’ restorations you have in mind.

THE GUIDE™ RESIN ADVANTAGE

High Precision

The high accuracy of this material allows for easy-to-insert drill sleeves, realises glue channels, positioning windows, and drill holes.

BIO Compatible

Registered Class I material TGA. It is transparent, odourless and tasteless once cleaned and post-cured.

Autoclavable

Once cured, this material is suitable for sterilisation using standard autoclave protocols. The mechanical properties provide the ultimate implant assistance.

WHICH GUIDE™ FORMULA SUITS YOUR 3D PRINTER?

GUIDE™ BIO Dental Resin is available in two formulas. Since DLP printers output more power than MSLA, we have a version to cover both system types.

Choose the DLP formula if your printer uses a projector module (DLP) to expose the layers. These include brands and models such as the MoonRay, SprintRay, Peopoly Moai, Asiga UV-Max & Pro 4K, Phrozen Make, B9 Creator, Flashforge Hunter, XYZ Nobel, and Kudo Titan.

If your 3D printer uses an LCD screen and a LED array (MSLA) to expose the layers, you must use our regular MSLA formula. These include Anycubic, Phrozen, Creality, Elegoo, Epax, Peopoly, Prusa, Uniz, Wanhao, WOW SparkMaker & Kelant.

ABOUT GUIDE™ BIO DENTAL RESIN

Monocure 3D GUIDE™ bio-compatible dental 3D resin has been engineered to fabricate surgical guides. Once post-cured, this material has high tensile strength and is transparent, odourless and tasteless. It has a high heat resistance and is suitable for sterilisation using standard autoclave protocols.

Monocure 3D’s Surgical GUIDE™ is transparent biocompatible registered Class I material. Our Chemists developed it for high-precision implant-guided surgeries. The high-resolution, rapid layer speed and exceptional mechanical properties provide the ultimate implant assistance.

This resin is available in two formulas for MSLA and DLP 3D printers. It can print within a wide range of UV, between 365 and 405nm.

GUIDE™ - PHYSICAL PROPERTIES (MSLA)

SKUs

M/BIOM-3990C

Colour(s)

Transparent

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1.5-3 seconds per layer (Monochrome LCD)

Storage

Dark, cool & dry place

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible MSLA Printers

- Anycubic

- Phrozen

- Creality

- Elegoo

- Epax

- Peopoly

- Prusa

- Uniz

- Wanhao

- WOW SparkMaker

- Kelant

- Not Listed – Contact Us

GUIDE™ - PHYSICAL PROPERTIES (DLP)

Product Code(s)

M/BIOD-3990C

Colour(s)

Transparent

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1-3 seconds per layer

Storage

Dark, cool & dry place.

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible Printers

- Asiga

- SprintRay

- Peopoly

- MoonRay

- Phrozen Make

- B9 Creator

- Flashforge Hunter

- XYZ Nobel

- Kudo Titan

- Not Listed – Contact Us

Monocure 3D

Australian Made

LOCALLY MADE PRODUCTS EQUALS LOCAL SUPPORT. THE AUSSIE 3D PRINTING BRAND WITH OVER 30 YEARS OF MANUFACTURING EXPERIENCE.

Monocure 3D is at the forefront of Australia’s Dental 3D Printer Resin industry. We are the local leaders of UV technology with more than 35 years of product development and manufacturing experience. The team at Monocure 3D have been working closely with Dental Labs locally and abroad to develop the ultimate Dental 3D Printer Resin.

All our resins are manufactured in Australia using the highest quality materials, following strict ISO 9001 guidelines. Our QC chemists test every batch as we know how important consistency is. Since we manufacture locally, you can say goodbye to supply chain problems.

Related Products

Monocure 3D Plate Bond 30ml - Build Plate Adhesion Aid

Monocure 3D Plate Bond 30ml Monocure 3D PLATEBOND™ is a UV cured build plate adhesion promo..

Monocure 3D RESINAWAY - Non-flammable UV resin cleaning solution - 20L Drum

Monocure 3D RESINAWAY The Ultimate Resin Cleaning Solution - No harsh chemicals - Long Lasting..

Monocure 3D RESINAWAY - Non-flammable UV resin cleaning solution - 5L Bottle

Monocure 3D RESINAWAY The Ultimate Resin Cleaning Solution - No harsh chemicals - Long Las..

Monocure 3D PRECISE HD Dental Model Resin - For higher end 3D dental models and thermoforming - 1L - ALMOND ** DLP Formula Resin **

Monocure 3D PRECISE™ HD – Dental Model Resin PRECISE&tra..

Monocure 3D PRECISE HD Dental Model Resin - For higher end 3D dental models and thermoforming - 5L - ALMOND ** DLP Formula Resin **

Monocure 3D PRECISE™ HD – Dental Model Resin PRECISE™ dental 3D ..

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Dental Resin - MSLA Resin - TRANSPARENT - 1L - Australian Made - INI File Supported for your printer ** MSLA Formula Resin ** - SPECIAL ORDER ITEM

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Monocure 3D GUIDE™ b..

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Dental Resin - DLP Resin - TRANSPARENT - 5L - Australian Made - INI File Supported for your printer ** DLP Formula Resin ** - SPECIAL ORDER ITEM

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Monocure 3D GUIDE™ bio-c..

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Dental Resin - TRANSPARENT - 5L - Australian Made - INI File Supported for your printer ** MSLA Formula Resin ** - SPECIAL ORDER ITEM

Monocure 3D GUIDE BIO (Surgical Guide Biocompatible) Monocure 3D GUIDE™ bio-compatibl..

Monocure 3D RESINAWAY EZY-WIPES - 3D Resin Cleaning Wipes - 1 Canister (100 Wipes)

Monocure 3D RESINAWAY EZY-WIPES Monocure 3D RESINAWAY EZY-WIPES are a multi-purpose solution to..

Monocure 3D THERMO Heat Resistant Dental Model Resin - Specifically designed for thermoforming orthodontic aligners and mouthguards - 5L LARGE BOTTLE - GREY - DLP or MSLA Resin

Monocure 3D THERMO™ – Heat Resistant Dental Model Resin ..

Monocure 3D THERMO Heat Resistant Dental Model Resin - Specifically designed for thermoforming orthodontic aligners and mouthguards - 1L - GREY - DLP or MSLA Resin

Monocure 3D THERMO™ – Heat Resistant Dental Model Resin ..