- Products

- 3D Printing Consumables

- 3D PRINTING RESINS - DLP AND MSLA FORMULAS

- TEMP C&B Resin (DLP)

- Kulzer DIMA Print Resin - Crown and Bridge TEMP 1000g - Shade Options Available

Kulzer DIMA Print Resin - Crown and Bridge TEMP 1000g - Shade Options Available

- Brand: Kulzer

- Product Code: K-DT-**

Kulzer DIMA Print Resin - Crown and Bridge Temp 1000g - Shade Options Available

NOTE:

CURRENLY ONLY A1, A2, BL1 SHADES IN STOCK

ALL OTHERS WILL BE SPECIAL ORDER ex SYDNEY

Validated ONLY for use with Asiga Printers, Kulzer Cara Printers and Kulzer LED Curing Process

IFU - Instructions For Use

ARTG: 383571

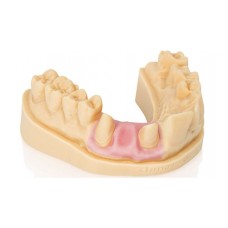

dima Print C&B temp is a Class IIa material that can be used to produce short-term Try-ins or longerterm temporaries (up to 1 year). The material covers exposed dentine, minimizing or completely preventing sensitivity.

Furthermore, temporaries made with dima Print C&B temp serve as an excellent basis for assessing the fit, shade, shape, position of contacts and more – all before the final restoration is made. For dental technicians already using the cara Print System, dima Print C&B temp integrates perfectly into existing workflows.

Don’t mill it, print! For faster temporaries and provisionals.

-

Class IIa material for short-term Try-ins or longer-term temporaries (up to 1 year)

-

Up to 6-unit anterior bridges and 4-unit posterior bridges

-

Easy verification of shade, shape, midlines, smile line, embrasure & position with Try-ins

-

Covers exposed dentine, therefore minimizes or completely prevents sensitivity

-

Available in 7 shades: A1, A2, A3, A3.5, B1, B2, BL1

When it comes to temporaries and provisionals, 3D printing saves a significant amount of time and costs when compared to milling. But not only that: it frees up dental mills for higher value jobs that are not possible on a 3D printer (e.g. zirconia). Particularly for in-house technicians, 3D printing can deliver a perfectly fitting and aesthetically pleasing temporary in less than 1 hour after a patient’s teeth are prepped for a new crown or bridge.

Achieve higher productivity through 3D printed temporaries and provisionals instead of milling

-

Time saving: e.g. only 30 minutes to print 30 crowns vs. 450 minutes needed for milling

-

Cost saving: costs for a printed crown approx. €0.33 vs. €1.00 for milling

Achieve higher profitability and increase ROI for your milling machine

-

Free up milling machine capacity: save it for the fabrication of high-value products (e.g. zirconia)

-

In-house labs have less time pressure: patients get printed temporaries in just under 1 hour, which means more time to prepare the permanent crown or bridge

| Product overview | ||||

|---|---|---|---|---|

| Flexural Strength (Mpa) | Flexual Modulus (Mpa) | Cleaning time in Isopropanol (cara Print Clean or ultra sonic bath) |

Post-curing time (HiLite Power 3D) |

Post-Curing time LEDcure (no turning of object necessary) |

| > 50 | > 2000 | pre-cleaning: 3 minutes post-cleaning: 2 minutes |

20 minutes (10 minutes front side +10 minutes reverse side) in Glycerin |

C&B Temp program, cure in Glycerin |

Kulzer DIMA Print Resin - Crown and Bridge TEMP 1000g - Shade Options Available

- Brand: Kulzer

- Product Code: K-DT-**

Available Options

Kulzer DIMA Print Resin - Crown and Bridge Temp 1000g - Shade Options Available

NOTE:

CURRENLY ONLY A1, A2, BL1 SHADES IN STOCK

ALL OTHERS WILL BE SPECIAL ORDER ex SYDNEY

Validated ONLY for use with Asiga Printers, Kulzer Cara Printers and Kulzer LED Curing Process

IFU - Instructions For Use

ARTG: 383571

dima Print C&B temp is a Class IIa material that can be used to produce short-term Try-ins or longerterm temporaries (up to 1 year). The material covers exposed dentine, minimizing or completely preventing sensitivity.

Furthermore, temporaries made with dima Print C&B temp serve as an excellent basis for assessing the fit, shade, shape, position of contacts and more – all before the final restoration is made. For dental technicians already using the cara Print System, dima Print C&B temp integrates perfectly into existing workflows.

Don’t mill it, print! For faster temporaries and provisionals.

-

Class IIa material for short-term Try-ins or longer-term temporaries (up to 1 year)

-

Up to 6-unit anterior bridges and 4-unit posterior bridges

-

Easy verification of shade, shape, midlines, smile line, embrasure & position with Try-ins

-

Covers exposed dentine, therefore minimizes or completely prevents sensitivity

-

Available in 7 shades: A1, A2, A3, A3.5, B1, B2, BL1

When it comes to temporaries and provisionals, 3D printing saves a significant amount of time and costs when compared to milling. But not only that: it frees up dental mills for higher value jobs that are not possible on a 3D printer (e.g. zirconia). Particularly for in-house technicians, 3D printing can deliver a perfectly fitting and aesthetically pleasing temporary in less than 1 hour after a patient’s teeth are prepped for a new crown or bridge.

Achieve higher productivity through 3D printed temporaries and provisionals instead of milling

-

Time saving: e.g. only 30 minutes to print 30 crowns vs. 450 minutes needed for milling

-

Cost saving: costs for a printed crown approx. €0.33 vs. €1.00 for milling

Achieve higher profitability and increase ROI for your milling machine

-

Free up milling machine capacity: save it for the fabrication of high-value products (e.g. zirconia)

-

In-house labs have less time pressure: patients get printed temporaries in just under 1 hour, which means more time to prepare the permanent crown or bridge

| Product overview | ||||

|---|---|---|---|---|

| Flexural Strength (Mpa) | Flexual Modulus (Mpa) | Cleaning time in Isopropanol (cara Print Clean or ultra sonic bath) |

Post-curing time (HiLite Power 3D) |

Post-Curing time LEDcure (no turning of object necessary) |

| > 50 | > 2000 | pre-cleaning: 3 minutes post-cleaning: 2 minutes |

20 minutes (10 minutes front side +10 minutes reverse side) in Glycerin |

C&B Temp program, cure in Glycerin |

Related Products

Kulzer Hilite Power 3D - Light Curing Unit - High Powered Strobe Quick Light Curing Unit For Many Applications 66069514 (Xenon Stroboscope Flash Bulb) - 1 UNIT

Kulzer HiLite power 3D is our all-rounder High Power strobe light curing unit. RRP $464..

Kulzer cara Print LEDcure Light Curing Unit (LED Style) For 3D Print Resins - 66078521 - 1 Unit

SPECIAL ORDER ITEM - 1 WEEK LEADTIME Kulzer cara Print LEDcure Light Curing Unit (LED Style) For ..

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666 Validated ONLY for use wit..

Kulzer DIMA Print Resin - Denture Base 1000g - Shade Options Available

Kulzer DIMA Print Resin - Denture Base 1000g - Shade Options Available Validated ONLY for use wit..

Kulzer DIMA Print Resin - Denture Teeth 1000g - Shade Options Available

Kulzer DIMA Print Resin - Denture Teeth 1000g - Shade Options Available MD - Validated ONLY for u..

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664 IFU - Instructions For Use CAD-to-Ca..

Kulzer DIMA Print Resin - Gingiva Mask 1000g - 66077884

Kulzer DIMA Print Resin - Gingiva Mask 1000g - 66077884 IFU - Instructions For Use A perf..

Kulzer DIMA Print Resin - Guide & Tray 1000g - 66081915

Kulzer DIMA Print Resin - Guide & Tray 1000g - 66081915 Validated ONLY for use with Asiga Pri..

Kulzer DIMA Print Resin - Splint Hard - Clear 1000g - 66077916

Kulzer DIMA Print Resin - Splint Hard - Clear 1000g - 66077916 Validated ONLY for use with Asiga ..

Kulzer DIMA Print Resin - Stone (Model) 1000g - Colour Options Available

Kulzer DIMA Print Resin - Stone 1000g - Colour Options Available Validated with Asiga Printers, K..

Detax Freeprint SPLINTMASTER FLEX 385 DLP 3D Printing Resin 04432 - 1000g

3D Print Resin Stock Holding Information and Leadtimes: Initally given the nature of the digital la..

NK Optik Otoflash G171-6 with N2 Nitrogen GAS PORT Light Curing Unit - Stroboscopic-Light - 1 Unit

NK Optik Otoflash G171-6 with N2 GAS PORT - 1 Unit With Nitrogen attachment for CE requirements..