- Products

- 3D Printing Consumables

- 3D PRINTING RESINS - DLP AND MSLA FORMULAS

- Kulzer DIMA Print Resins

- Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666

- Brand: Kulzer

- Product Code: K-DTI-W

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666

Validated ONLY for use with Asiga Printers, Kulzer Cara Printers and Kulzer LED Curing / Hilite Power 3D Process

IFU - Instructions For Use

ARTG: 383305 (Denture Try-In/Base) 383352 (Teeth)

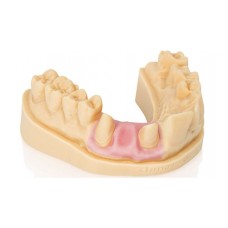

With dima Print Digital Denture, technicians can fully produce a good quality back-up denture using the fast and secure cara 3D printing workflow.

The digital denture solution consists of three class IIa (2A) materials:

- dima Print Denture Base Try-in for the production of Try-ins.

- dima Print Denture Base for the production of high-quality duplicate denture bases with multiple shade options.

- dima Print Denture Teeth for the production of high-quality duplicate denture teeth with multiple shade options.

More time for other things

- Fast production time and less stress: produce a fully 3D printed denture in just under 2 hours!

- Easy to learn: 3D fabrication process is easy to learn and hand off among colleagues.

- For cara printer users: use a known and secure process to fabricate a fully digital denture with minimal effort.

- Less stress and time pressure: more time to repair a broken denture since the patient has a duplicate denture as back-up.

Higher profitability

- A fast and cost-effective digital solution to produce Try-ins and full dentures, e.g. as back-up or travel dentures.

- Total material cost for fully 3D printed denture approx. €10.81 for upper and €12.45 for lower arch.

- Exceptionally precise results with 3D printed dentures.

- Gain new dentist customers by offering a new profitable business area.

Curing recommendations:

- dima Print Denture Base Try-in, dima Print Denture Base and dima Print Denture Teeth materials must all be post-cured with an oxygen inhibitor (nitrogen gas or glycerin) to remove unreacted functional groups and create harder surfaces. Kulzer recommend using 99 % glycerin.

- Curing Time

- Hilite Power 3D – 20 Minutes

- cara LEDcure – up to 30 Minutes

- Curing Time

Using glycerin in Kulzer Light curing devices:

Glycerin is a non-flammable liquid that can be used in Kulzer light curing devices when handled with care:

- To cure the objects in glycerin you need an up to 80 °C heat-resistant glass bowl with a glass lid, which fits in your light curing device.

- The printed object must be covered with glycerin completely

- Glycerin can be reused and only needs to be changed when getting foggy

Finishing:

- Once post-curing is complete, grind the support spots and borders of the fabricated denture to make it smooth.

- Pumice and polish the denture using conventional method with a polishing unit using desired pumice.

- Kulzer recommend using Pala Polish for achieving a high shine for the fully printed denture.

| Product Overview | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MDD class | Color | Flexural Strength (Mpa) | Flexual Modulus (Mpa) | Cleaning time in isopropanol cara Print Clean |

Post-curing time HiLite Power 3D | Post-Curing time LEDcure (no turning of object necessary) |

||||||||

| IIa | White | > 65 | > 2000 | pre-cleaning: 3 minutes post-cleaning: 2 minutes |

20 minutes (10 minutes front side +10 minutes reverse side) in Glycerin |

Try-in program, cure in Glycerin |

||||||||

| Printing Performance Overview | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Example | Build height [mm] | Time [min] for 50 µm resolution | Time [min] for 100 µm resolution | Material consumption [ml] | Avg. material costs/part [€] | |||||||||

| Try-in one upper arch |

1147 | - | 43 | 26.24 | 8.92 | |||||||||

| Try-in one lower arch |

1130 | - | 42 | 18.20 | 8.92 | |||||||||

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666

- Brand: Kulzer

- Product Code: K-DTI-W

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666

Validated ONLY for use with Asiga Printers, Kulzer Cara Printers and Kulzer LED Curing / Hilite Power 3D Process

IFU - Instructions For Use

ARTG: 383305 (Denture Try-In/Base) 383352 (Teeth)

With dima Print Digital Denture, technicians can fully produce a good quality back-up denture using the fast and secure cara 3D printing workflow.

The digital denture solution consists of three class IIa (2A) materials:

- dima Print Denture Base Try-in for the production of Try-ins.

- dima Print Denture Base for the production of high-quality duplicate denture bases with multiple shade options.

- dima Print Denture Teeth for the production of high-quality duplicate denture teeth with multiple shade options.

More time for other things

- Fast production time and less stress: produce a fully 3D printed denture in just under 2 hours!

- Easy to learn: 3D fabrication process is easy to learn and hand off among colleagues.

- For cara printer users: use a known and secure process to fabricate a fully digital denture with minimal effort.

- Less stress and time pressure: more time to repair a broken denture since the patient has a duplicate denture as back-up.

Higher profitability

- A fast and cost-effective digital solution to produce Try-ins and full dentures, e.g. as back-up or travel dentures.

- Total material cost for fully 3D printed denture approx. €10.81 for upper and €12.45 for lower arch.

- Exceptionally precise results with 3D printed dentures.

- Gain new dentist customers by offering a new profitable business area.

Curing recommendations:

- dima Print Denture Base Try-in, dima Print Denture Base and dima Print Denture Teeth materials must all be post-cured with an oxygen inhibitor (nitrogen gas or glycerin) to remove unreacted functional groups and create harder surfaces. Kulzer recommend using 99 % glycerin.

- Curing Time

- Hilite Power 3D – 20 Minutes

- cara LEDcure – up to 30 Minutes

- Curing Time

Using glycerin in Kulzer Light curing devices:

Glycerin is a non-flammable liquid that can be used in Kulzer light curing devices when handled with care:

- To cure the objects in glycerin you need an up to 80 °C heat-resistant glass bowl with a glass lid, which fits in your light curing device.

- The printed object must be covered with glycerin completely

- Glycerin can be reused and only needs to be changed when getting foggy

Finishing:

- Once post-curing is complete, grind the support spots and borders of the fabricated denture to make it smooth.

- Pumice and polish the denture using conventional method with a polishing unit using desired pumice.

- Kulzer recommend using Pala Polish for achieving a high shine for the fully printed denture.

| Product Overview | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MDD class | Color | Flexural Strength (Mpa) | Flexual Modulus (Mpa) | Cleaning time in isopropanol cara Print Clean |

Post-curing time HiLite Power 3D | Post-Curing time LEDcure (no turning of object necessary) |

||||||||

| IIa | White | > 65 | > 2000 | pre-cleaning: 3 minutes post-cleaning: 2 minutes |

20 minutes (10 minutes front side +10 minutes reverse side) in Glycerin |

Try-in program, cure in Glycerin |

||||||||

| Printing Performance Overview | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Example | Build height [mm] | Time [min] for 50 µm resolution | Time [min] for 100 µm resolution | Material consumption [ml] | Avg. material costs/part [€] | |||||||||

| Try-in one upper arch |

1147 | - | 43 | 26.24 | 8.92 | |||||||||

| Try-in one lower arch |

1130 | - | 42 | 18.20 | 8.92 | |||||||||

Related Products

Kulzer Hilite Power 3D - Light Curing Unit - High Powered Strobe Quick Light Curing Unit For Many Applications 66069514 (Xenon Stroboscope Flash Bulb) - 1 UNIT

Kulzer HiLite power 3D is our all-rounder High Power strobe light curing unit. RRP $464..

Kulzer DIMA Print Resin - Crown and Bridge TEMP 1000g - Shade Options Available

Kulzer DIMA Print Resin - Crown and Bridge Temp 1000g - Shade Options Available NOTE: CU..

Kulzer cara Print LEDcure Light Curing Unit (LED Style) For 3D Print Resins - 66078521 - 1 Unit

SPECIAL ORDER ITEM - 1 WEEK LEADTIME Kulzer cara Print LEDcure Light Curing Unit (LED Style) For ..

Kulzer DIMA Print Resin - Denture Base 1000g - Shade Options Available

Kulzer DIMA Print Resin - Denture Base 1000g - Shade Options Available Validated ONLY for use wit..

Kulzer DIMA Print Resin - Denture Teeth 1000g - Shade Options Available

Kulzer DIMA Print Resin - Denture Teeth 1000g - Shade Options Available MD - Validated ONLY for u..

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664 IFU - Instructions For Use CAD-to-Ca..

Kulzer DIMA Print Resin - Gingiva Mask 1000g - 66077884

Kulzer DIMA Print Resin - Gingiva Mask 1000g - 66077884 IFU - Instructions For Use A perf..

Kulzer DIMA Print Resin - Guide & Tray 1000g - 66081915

Kulzer DIMA Print Resin - Guide & Tray 1000g - 66081915 Validated ONLY for use with Asiga Pri..

Kulzer DIMA Print Resin - Splint Hard - Clear 1000g - 66077916

Kulzer DIMA Print Resin - Splint Hard - Clear 1000g - 66077916 Validated ONLY for use with Asiga ..

Kulzer DIMA Print Resin - Stone (Model) 1000g - Colour Options Available

Kulzer DIMA Print Resin - Stone 1000g - Colour Options Available Validated with Asiga Printers, K..

Detax Freeprint SPLINTMASTER FLEX 385 DLP 3D Printing Resin 04432 - 1000g

3D Print Resin Stock Holding Information and Leadtimes: Initally given the nature of the digital la..

NK Optik Otoflash G171-6 with N2 Nitrogen GAS PORT Light Curing Unit - Stroboscopic-Light - 1 Unit

NK Optik Otoflash G171-6 with N2 GAS PORT - 1 Unit With Nitrogen attachment for CE requirements..

Monocure 3D PRECISE PLUS HD Dental Model Resin - 5L - ALMOND - DLP Resin

Monocure 3D UPDATED FORMULA 11/24 REPLACES PRECISE PRECISE+ Dental Mode..