- Products

- 3D Printing Consumables

- 3D PRINTING RESINS - DLP AND MSLA FORMULAS

- Kulzer DIMA Print Resins

- Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664

- Brand: Kulzer

- Product Code: K-DC-R

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664

IFU - Instructions For Use

CAD-to-Cast: Increase precision, surface quality and reliability while saving time.

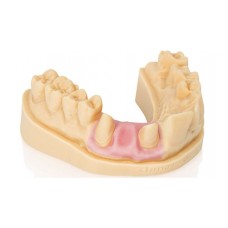

dima Print Cast ruby: a universal casting material that facilitates greater detail than milling (no bur size limits). Compatible with traditional materials and crowns and bridges (up to 5 units). In precious/non-precious metals, partials and inlays/onlays made with press ceramics.

The resin is very fluid yet avoids sedimentation for easy handling: create flexible clasps, highly precise detailing and crown margins with a resolution of 50μm. The final surfaces come out very smooth following residue-free burnout.

One material for all cast indications and a secure production process.

- Smooth & detailed cast metal surfaces.

- Residue-free burn out.

- Perfect for precious metals, non-precious metals and press ceramics.

- For partials, crowns and bridges (up to 5 units) and inlays/onlays.

- Compatible with traditional materials.

- Full portfolio for optimal results: casting equipment, investment materials, alloys, etc. all perfectly matched from a single provider.

| Product Overview | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| MDD class | Color | Flexural Strength (Mpa) | Flexual Modulus (Mpa) | Viscosity [mPa*sec] | Printing time per part | ||||

| not applicable | red | not applicable | not applicable | 125 | 32 min (50 μm in z, 32 crowns) |

||||

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664

- Brand: Kulzer

- Product Code: K-DC-R

Kulzer DIMA Print Resin - Cast Ruby 1000g - 66081664

IFU - Instructions For Use

CAD-to-Cast: Increase precision, surface quality and reliability while saving time.

dima Print Cast ruby: a universal casting material that facilitates greater detail than milling (no bur size limits). Compatible with traditional materials and crowns and bridges (up to 5 units). In precious/non-precious metals, partials and inlays/onlays made with press ceramics.

The resin is very fluid yet avoids sedimentation for easy handling: create flexible clasps, highly precise detailing and crown margins with a resolution of 50μm. The final surfaces come out very smooth following residue-free burnout.

One material for all cast indications and a secure production process.

- Smooth & detailed cast metal surfaces.

- Residue-free burn out.

- Perfect for precious metals, non-precious metals and press ceramics.

- For partials, crowns and bridges (up to 5 units) and inlays/onlays.

- Compatible with traditional materials.

- Full portfolio for optimal results: casting equipment, investment materials, alloys, etc. all perfectly matched from a single provider.

| Product Overview | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| MDD class | Color | Flexural Strength (Mpa) | Flexual Modulus (Mpa) | Viscosity [mPa*sec] | Printing time per part | ||||

| not applicable | red | not applicable | not applicable | 125 | 32 min (50 μm in z, 32 crowns) |

||||

Related Products

Kulzer Hilite Power 3D - Light Curing Unit - High Powered Strobe Quick Light Curing Unit For Many Applications 66069514 (Xenon Stroboscope Flash Bulb) - 1 UNIT

Kulzer HiLite power 3D is our all-rounder High Power strobe light curing unit. RRP $464..

Kulzer DIMA Print Resin - Crown and Bridge TEMP 1000g - Shade Options Available

Kulzer DIMA Print Resin - Crown and Bridge Temp 1000g - Shade Options Available NOTE: CU..

Kulzer cara Print LEDcure Light Curing Unit (LED Style) For 3D Print Resins - 66078521 - 1 Unit

SPECIAL ORDER ITEM - 1 WEEK LEADTIME Kulzer cara Print LEDcure Light Curing Unit (LED Style) For ..

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666

Kulzer DIMA Print Resin - Denture Base TRY IN - White 1000g - 66081666 Validated ONLY for use wit..

Kulzer DIMA Print Resin - Denture Base 1000g - Shade Options Available

Kulzer DIMA Print Resin - Denture Base 1000g - Shade Options Available Validated ONLY for use wit..

Kulzer DIMA Print Resin - Denture Teeth 1000g - Shade Options Available

Kulzer DIMA Print Resin - Denture Teeth 1000g - Shade Options Available MD - Validated ONLY for u..

Kulzer DIMA Print Resin - Gingiva Mask 1000g - 66077884

Kulzer DIMA Print Resin - Gingiva Mask 1000g - 66077884 IFU - Instructions For Use A perf..

Kulzer DIMA Print Resin - Guide & Tray 1000g - 66081915

Kulzer DIMA Print Resin - Guide & Tray 1000g - 66081915 Validated ONLY for use with Asiga Pri..

Kulzer DIMA Print Resin - Splint Hard - Clear 1000g - 66077916

Kulzer DIMA Print Resin - Splint Hard - Clear 1000g - 66077916 Validated ONLY for use with Asiga ..

Kulzer DIMA Print Resin - Stone (Model) 1000g - Colour Options Available

Kulzer DIMA Print Resin - Stone 1000g - Colour Options Available Validated with Asiga Printers, K..

NK Optik Otoflash G171-6 with N2 Nitrogen GAS PORT Light Curing Unit - Stroboscopic-Light - 1 Unit

NK Optik Otoflash G171-6 with N2 GAS PORT - 1 Unit With Nitrogen attachment for CE requirements..