- Products

- 3D Printing Consumables

- 3D PRINTING RESINS - DLP AND MSLA FORMULAS

- MODEL 3D Printer Resins (DLP / MSLA)

- Monocure 3D THERMO Heat Resistant Dental Model Resin - 1L - GREY - DLP Resin

Monocure 3D THERMO Heat Resistant Dental Model Resin - 1L - GREY - DLP Resin

- Brand: Monocure 3D

- Product Code: M3D-T-DLP-1

Monocure 3D

THERMO™ – Heat Resistant Dental Model Resin

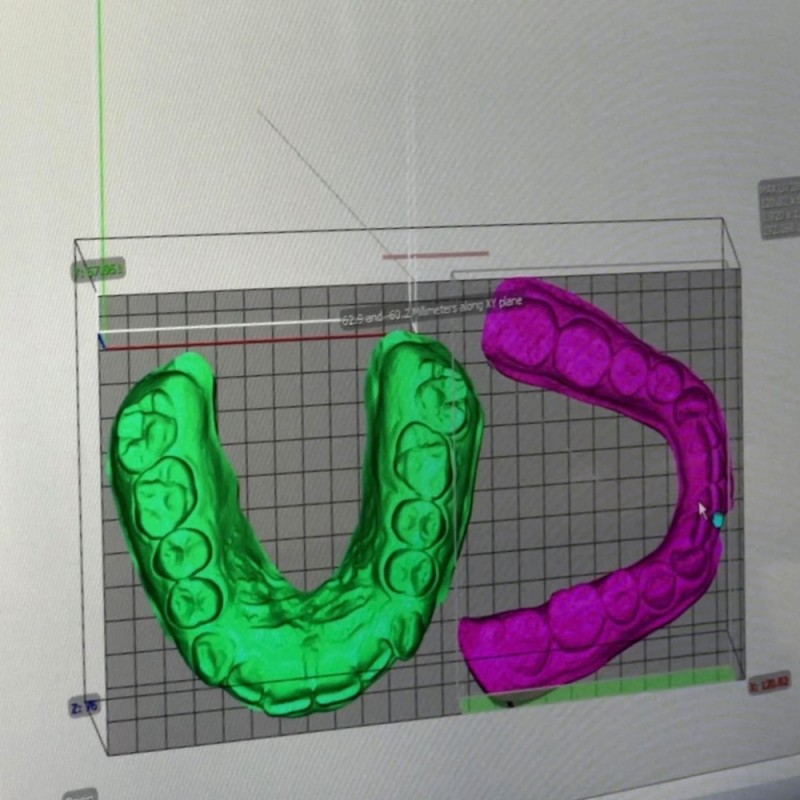

Monocure 3D THERMO™ Heat Resistant Dental Model Resin is a 3D printing material specifically designed for orthodontic aligners and mouthguards. This advanced resin offers exceptional heat resistance and pressure vacuum forming capabilities, ensuring optimal durability and precision for your dental applications.

Thermo Heat Resistant Resin was developed for Pressure and Vacuum forming. These are two essential processes used in the production of 3D-printed dental models.

Pressure forming involves the application of air pressure to a 3D printed model to fill in teh details and create a more accurate and realistic representation of the desired model. Vacuum forming, on the other hand, uses a vacuum to suck the material onto the model and create a more detailes and accurate model.

Both processes are used to create dental models that are accurate, durable and aesthetically pleasing. These processes are made even more accessible and reliable using a specially designed 3D printing resin, like Monocure 3D THERMO Heat Resistant Resin.

With superior heat resistance and pressure vacuum forming, Monocure 3D THERMO Heat Resistant Resin is the perfect choice for creating 3D printed dental models.

THERMO™ Heat Resistant Dental Model Resin is available in two formulas:

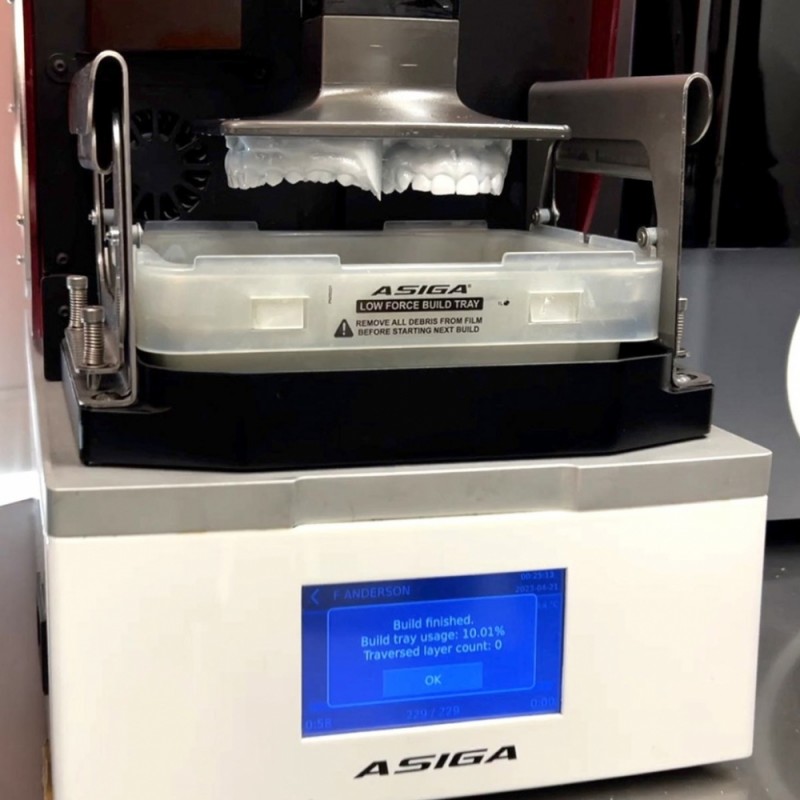

Choose the DLP formula if your printer uses a projector module (DLP) to expose the layers. These include brands and models such as the MoonRay, SprintRay, Peopoly Moai, Asiga UV-Max & Pro 4K, Phrozen Make, B9 Creator, Flashforge Hunter, XYZ Nobel, and Kudo Titan.

If your 3D printer uses an LCD screen and a LED array (MSLA) to expose the layers, you must use our regular MSLA formula. These include Anycubic, Phrozen, Creality, Elegoo, Epax, Peopoly, Prusa, Uniz, Wanhao, WOW SparkMaker & Kelant.

If your printer is not listed here, please Contact Us.

Our quality control procedures follow the ISO 9001 guidelines to ensure batch-to-batch consistency in every bottle of dental model resin. We call this the ‘set and forget methodology’, meaning you only have to dial our resin once. Then it’s as simple as pour and print, giving you more time to focus on what’s important. The unique low viscosity formula means lower print failures in colder weather, allowing consistent results all year round.

Monocure 3D PRECISE™ Dental model resin is not approved for intraoral use.

ASIGA MACHINES SETTINGS INI ZIP FILE DOWNLOAD

HOW TO LOAD INI SETTING FILES

THERMO™ SATISFACTION GUARANTEED

High Heat Resistance (120°C)

Specially designed to provide superior heat resistance, making it the perfect choice for models that need to stand up to higher temperatures.

High Precision

THERMO™ Heat Resistant Resin is designed to provide high precision, allowing for detailed and dimensionally accurate 3D printed models.

'Easy Release'

This resin is designed witha n 'easy-release' formula, making it simple and easy to release mouth guards and aligners from the model after forming.

Multi-compatible formulas

The resin is designed to be compatible with DLP and MSLA 3D printing technologies, making it perfect for high-quality results with either technology.

THERMO™ 3D PRINTING PROTIPS

- We recommend positioning the model flat on the build plate without supports or hollowing the model.

- Post-curing a 3D-printed model is essential before pressure or vacuum forming. It ensures that the model is sufficiently cured and ready to withstand the pressure and heat of the thermo-forming process.

- A calibration model is an effective way to dial in a 3D resin printer for use with our THERMO™ resin, ensuring the printer & resin work together to produce highly-accurate models.

- To ensude the model is properly cleaned, we recommend RESINAWAY® to remove any trapped resin that can cause dimensional issues.

THERMO™ HEAT RESISTANT DENTAL MODEL RESIN AT A GLANCE

Heat Resistant Resin is an innovative 3D printing resin perfect for projects requiring superior heat resistance and pressure vacuum forming. This resin is designed for both MSLA and DLP technologies, is easy to print and boasts a smooth finish with an 'easy-release' formula.

With excellent accuracy, it can print with higher speeds and lower failure rates than competitors. The resin is designed to suit layer heights from 10 to 100 microns and has a low odour. With Monocure 3D THERMO™ Heat Resistant Resin, you can create models easily and confidently, knowing that it is resistant up to 120°C.

Monocure 3D

Australian Made

LOCALLY MADE PRODUCTS EQUALS LOCAL SUPPORT. THE AUSSIE 3D PRINTING BRAND WITH OVER 30 YEARS OF MANUFACTURING EXPERIENCE.

Monocure 3D is at the forefront of Australia’s Dental 3D Printer Resin industry. We are the local leaders of UV technology with more than 35 years of product development and manufacturing experience. The team at Monocure 3D have been working closely with Dental Labs locally and abroad to develop the ultimate Dental 3D Printer Resin.

All our resins are manufactured in Australia using the highest quality materials, following strict ISO 9001 guidelines. Our QC chemists test every batch as we know how important consistency is. Since we manufacture locally, you can say goodbye to supply chain problems.

Monocure 3D THERMO Heat Resistant Dental Model Resin - 1L - GREY - DLP Resin

- Brand: Monocure 3D

- Product Code: M3D-T-DLP-1

Available Options

Monocure 3D

THERMO™ – Heat Resistant Dental Model Resin

Monocure 3D THERMO™ Heat Resistant Dental Model Resin is a 3D printing material specifically designed for orthodontic aligners and mouthguards. This advanced resin offers exceptional heat resistance and pressure vacuum forming capabilities, ensuring optimal durability and precision for your dental applications.

Thermo Heat Resistant Resin was developed for Pressure and Vacuum forming. These are two essential processes used in the production of 3D-printed dental models.

Pressure forming involves the application of air pressure to a 3D printed model to fill in teh details and create a more accurate and realistic representation of the desired model. Vacuum forming, on the other hand, uses a vacuum to suck the material onto the model and create a more detailes and accurate model.

Both processes are used to create dental models that are accurate, durable and aesthetically pleasing. These processes are made even more accessible and reliable using a specially designed 3D printing resin, like Monocure 3D THERMO Heat Resistant Resin.

With superior heat resistance and pressure vacuum forming, Monocure 3D THERMO Heat Resistant Resin is the perfect choice for creating 3D printed dental models.

THERMO™ Heat Resistant Dental Model Resin is available in two formulas:

Choose the DLP formula if your printer uses a projector module (DLP) to expose the layers. These include brands and models such as the MoonRay, SprintRay, Peopoly Moai, Asiga UV-Max & Pro 4K, Phrozen Make, B9 Creator, Flashforge Hunter, XYZ Nobel, and Kudo Titan.

If your 3D printer uses an LCD screen and a LED array (MSLA) to expose the layers, you must use our regular MSLA formula. These include Anycubic, Phrozen, Creality, Elegoo, Epax, Peopoly, Prusa, Uniz, Wanhao, WOW SparkMaker & Kelant.

If your printer is not listed here, please Contact Us.

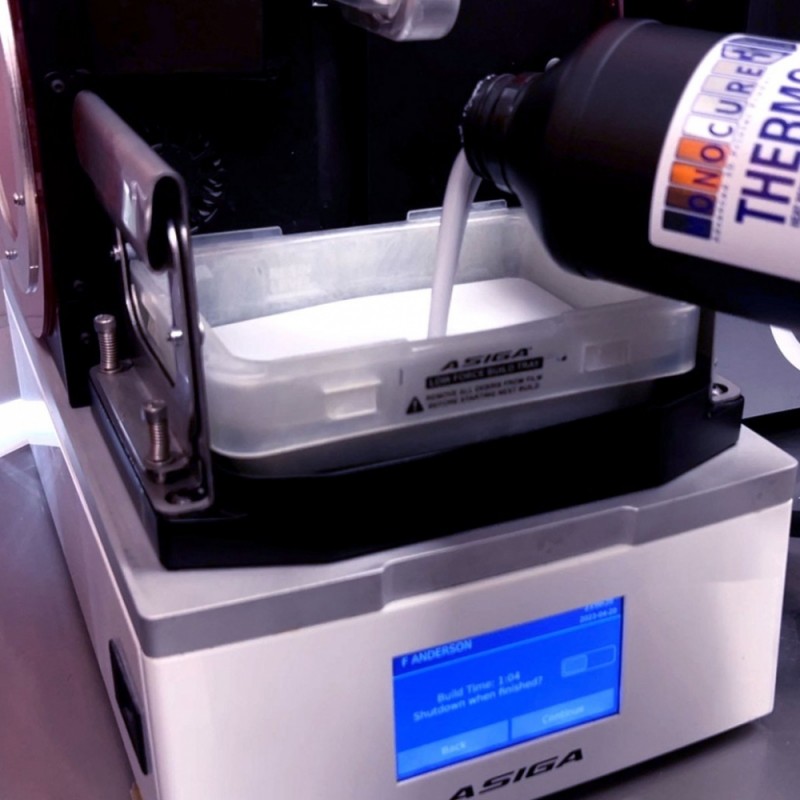

Our quality control procedures follow the ISO 9001 guidelines to ensure batch-to-batch consistency in every bottle of dental model resin. We call this the ‘set and forget methodology’, meaning you only have to dial our resin once. Then it’s as simple as pour and print, giving you more time to focus on what’s important. The unique low viscosity formula means lower print failures in colder weather, allowing consistent results all year round.

Monocure 3D PRECISE™ Dental model resin is not approved for intraoral use.

ASIGA MACHINES SETTINGS INI ZIP FILE DOWNLOAD

HOW TO LOAD INI SETTING FILES

THERMO™ SATISFACTION GUARANTEED

High Heat Resistance (120°C)

Specially designed to provide superior heat resistance, making it the perfect choice for models that need to stand up to higher temperatures.

High Precision

THERMO™ Heat Resistant Resin is designed to provide high precision, allowing for detailed and dimensionally accurate 3D printed models.

'Easy Release'

This resin is designed witha n 'easy-release' formula, making it simple and easy to release mouth guards and aligners from the model after forming.

Multi-compatible formulas

The resin is designed to be compatible with DLP and MSLA 3D printing technologies, making it perfect for high-quality results with either technology.

THERMO™ 3D PRINTING PROTIPS

- We recommend positioning the model flat on the build plate without supports or hollowing the model.

- Post-curing a 3D-printed model is essential before pressure or vacuum forming. It ensures that the model is sufficiently cured and ready to withstand the pressure and heat of the thermo-forming process.

- A calibration model is an effective way to dial in a 3D resin printer for use with our THERMO™ resin, ensuring the printer & resin work together to produce highly-accurate models.

- To ensude the model is properly cleaned, we recommend RESINAWAY® to remove any trapped resin that can cause dimensional issues.

THERMO™ HEAT RESISTANT DENTAL MODEL RESIN AT A GLANCE

Heat Resistant Resin is an innovative 3D printing resin perfect for projects requiring superior heat resistance and pressure vacuum forming. This resin is designed for both MSLA and DLP technologies, is easy to print and boasts a smooth finish with an 'easy-release' formula.

With excellent accuracy, it can print with higher speeds and lower failure rates than competitors. The resin is designed to suit layer heights from 10 to 100 microns and has a low odour. With Monocure 3D THERMO™ Heat Resistant Resin, you can create models easily and confidently, knowing that it is resistant up to 120°C.

Monocure 3D

Australian Made

LOCALLY MADE PRODUCTS EQUALS LOCAL SUPPORT. THE AUSSIE 3D PRINTING BRAND WITH OVER 30 YEARS OF MANUFACTURING EXPERIENCE.

Monocure 3D is at the forefront of Australia’s Dental 3D Printer Resin industry. We are the local leaders of UV technology with more than 35 years of product development and manufacturing experience. The team at Monocure 3D have been working closely with Dental Labs locally and abroad to develop the ultimate Dental 3D Printer Resin.

All our resins are manufactured in Australia using the highest quality materials, following strict ISO 9001 guidelines. Our QC chemists test every batch as we know how important consistency is. Since we manufacture locally, you can say goodbye to supply chain problems.

Related Products

Monocure 3D PRECISE HD Dental Model Resin - 1L - ALMOND - DLP Resin

Monocure 3D PRECISE™ HD – Dental Model Resin For higher ..

Monocure 3D PRECISE PLUS HD Dental Model Resin - 1L - ALMOND - MSLA Resin

Monocure 3D UPDATED FORMULA 11/24 REPLACES PRECISE PRECISE+ Dental Model Re..

Aldente Ausblockwachs Thermoforming Blockout Wax - White - 110g - 581-004-011

Aldente Ausblockwachs Thermoforming Blockout Wax - White - 110g - 581-004-011 For blocking out un..

Monocure 3D PRECISE PLUS HD Dental Model Resin - 1L - ALMOND - DLP Resin

Monocure 3D UPDATED FORMULA FROM 11/24 REPLACED PRECISE PRECISE+ Dental Model Re..