- Products

- Chrome Cobalt and Accessories

- Chrome Cobalt Alloys

- Kulzer Heraenium PW - Non precious bonding alloy -1kg - 66021871

Kulzer Heraenium PW - Non precious bonding alloy -1kg - 66021871

- Brand: Kulzer

- Product Code: K-HPW

SPECIAL ORDER or LOW STOCK HELD

MULTIBUY DISCOUNTS APPLY

Heraenium PW ‐Non precious bonding alloy for conventional ceramics.

Our Heraenium cobalt-chrome alloys are the result of intensive research.

The precious-metal-free alloys are economical alternatives that offer top quality. Heraenium alloys for crowns and bridges can be reliably veneered with ceramics from our HeraCeram lines and all other ceramics. HeraCeram NP-Primer ensures a secure bond between alloy and veneering ceramic even under critical oxidation conditions. It prevents uncontrolled formation of the oxide layer and dissolves it on the non-precious-metal surface as required to ensure optimum coating with ceramic. The basis for long-term aesthetics.

Benefits at a glance:

- good milling and polishing properties

- simple machining with low hardness

- free from beryllium and cadmium

- can be laser-welded and soldered

- very good corrosion resistance

Heraenium Pw

CoCr-based non-precious metal alloy

Cobalt-chrome-based bonding alloy for conventional ceramics especially for HeraCeram acc. to EN ISO 9693-1 and 22674

Advantages

- Heraenium Pw, a soft cobalt chromium bonding alloy for all indications.

- optimum physical properties for exceptional processing

- good milling and polishing properties

- simple machining with low hardness

- free from beryllium and cadmium

- Laserable and solderable

- very good corrosion resistance

Delivery form |

Art. code |

| 1 kg | 6602 1871 |

| 250 g | 6602 1872 |

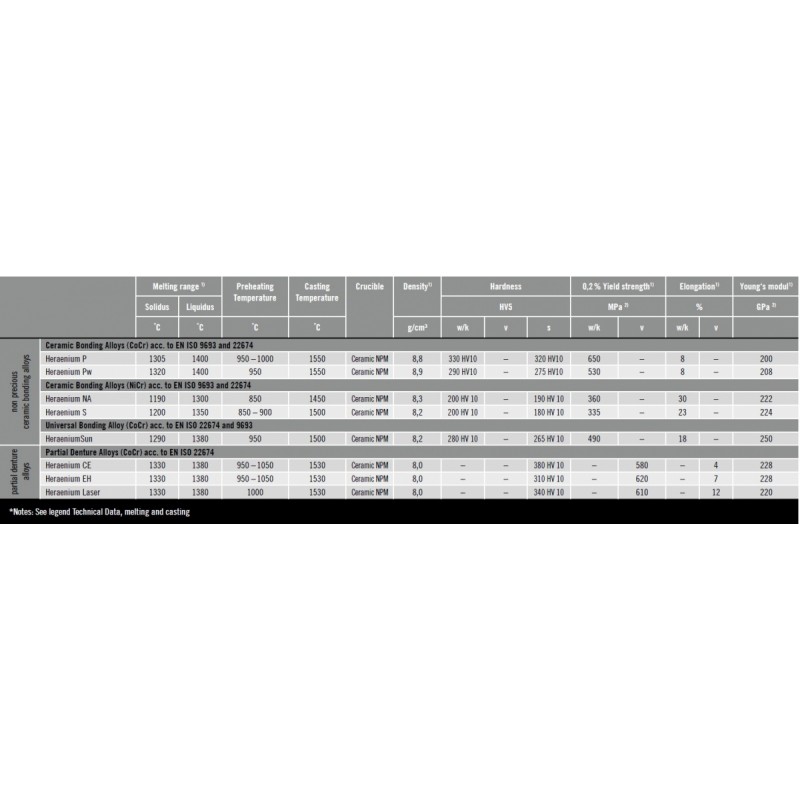

Technical specifications |

|

| Composition in mass % |

Co 55.2 | Cr 24.0 W 15.0 | Fe 4.0 Si 1.0 | Mn 0.8 N < 0.1 |

| Type | acc. to Guss Type 4 after ceramic firing Type 5 |

| Colour | white |

| Density (g/cm3) | 8.9 |

| Melting range (°C) | Solidus 1320 Liquidus 1400 |

| Hardness (HV 10) | after ceramic firing, 290 |

| 0.2 % yield strength (MPa) | after ceramic firing, 530 |

| Elongation (%) | after ceramic firing, 8 |

| CTE (25 – 500 °C) (μm/m*K) | 14.3 |

| Young's modulus of elasticity (GPa) | 208 |

Kulzer Heraenium PW - Non precious bonding alloy -1kg - 66021871

- Brand: Kulzer

- Product Code: K-HPW

SPECIAL ORDER or LOW STOCK HELD

MULTIBUY DISCOUNTS APPLY

Heraenium PW ‐Non precious bonding alloy for conventional ceramics.

Our Heraenium cobalt-chrome alloys are the result of intensive research.

The precious-metal-free alloys are economical alternatives that offer top quality. Heraenium alloys for crowns and bridges can be reliably veneered with ceramics from our HeraCeram lines and all other ceramics. HeraCeram NP-Primer ensures a secure bond between alloy and veneering ceramic even under critical oxidation conditions. It prevents uncontrolled formation of the oxide layer and dissolves it on the non-precious-metal surface as required to ensure optimum coating with ceramic. The basis for long-term aesthetics.

Benefits at a glance:

- good milling and polishing properties

- simple machining with low hardness

- free from beryllium and cadmium

- can be laser-welded and soldered

- very good corrosion resistance

Heraenium Pw

CoCr-based non-precious metal alloy

Cobalt-chrome-based bonding alloy for conventional ceramics especially for HeraCeram acc. to EN ISO 9693-1 and 22674

Advantages

- Heraenium Pw, a soft cobalt chromium bonding alloy for all indications.

- optimum physical properties for exceptional processing

- good milling and polishing properties

- simple machining with low hardness

- free from beryllium and cadmium

- Laserable and solderable

- very good corrosion resistance

Delivery form |

Art. code |

| 1 kg | 6602 1871 |

| 250 g | 6602 1872 |

Technical specifications |

|

| Composition in mass % |

Co 55.2 | Cr 24.0 W 15.0 | Fe 4.0 Si 1.0 | Mn 0.8 N < 0.1 |

| Type | acc. to Guss Type 4 after ceramic firing Type 5 |

| Colour | white |

| Density (g/cm3) | 8.9 |

| Melting range (°C) | Solidus 1320 Liquidus 1400 |

| Hardness (HV 10) | after ceramic firing, 290 |

| 0.2 % yield strength (MPa) | after ceramic firing, 530 |

| Elongation (%) | after ceramic firing, 8 |

| CTE (25 – 500 °C) (μm/m*K) | 14.3 |

| Young's modulus of elasticity (GPa) | 208 |

Related Products

Kulzer Heraenium EH - Chrome Cobalt - 310 Hardness HV10 / 620 MPa - 1kg - 64600956

MULTIBUY DISCOUNTS APPLY Fulfil the highest requirements: Our Heraenium non-precious metal for pa..

Kulzer Heraenium CE - Chrome Cobalt - 380 Hardness HV10 / 580 MPa - 1kg - 64600955

MULTIBUY DISCOUNTS APPLY Fulfil the highest requirements: Our Heraenium non-precious metal for pa..

Kulzer Heraenium NF - Chrome Cobalt - 360 Hardness HV10 / 720 MPa 1kg - 64601179

MULTIBUY DISCOUNTS APPLY Fulfil the highest requirements: Our Heraenium non-precious metal for pa..

Kulzer Heraenium LASER - Chrome Cobalt - 340 Hardness HV10 / 610 MPa - 1kg - 66008790

MULTIBUY DISCOUNTS APPLY Fulfil the highest requirements: Our Heraenium non-precious metal for pa..