- Products

- EQUIPMENT & Accessories

- Thermoforming Units

- Vacuum Forming Technology

- Keystone / Proform Vacuum Former Machine III (3) AU 220V 7000332

Keystone / Proform Vacuum Former Machine III (3) AU 220V 7000332

- Brand: Keystone Industries

- Product Code: K-VFM3

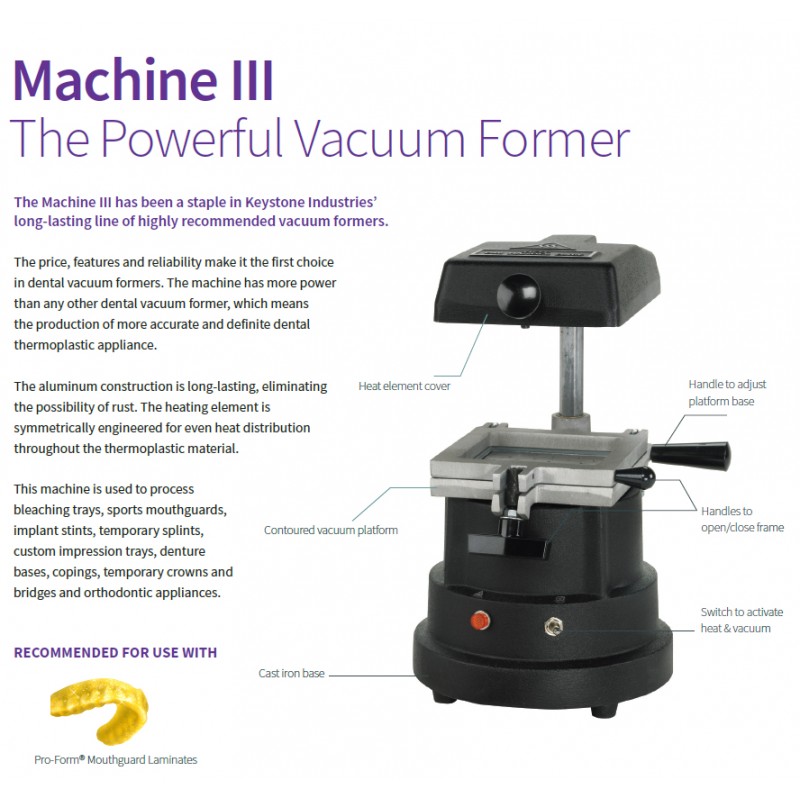

The Machine III has been a staple in Keystone Industries’ long-lasting line of highly recommended vacuum former machines.

Watch Keystone video online – how to use machine. Search Youtube - Keystone Pro-Form Basic Forming - CLICK HERE

The Machine III has been a staple in Keystone Industries’ long-lasting line of highly recommended vacuum former machines. The price, features and reliability make it the first choice in dental vacuum formers. The machine has more power than any other dental vacuum former, which means the production of more accurate and defined dental thermoplastic appliance.

The aluminum construction is long-lasting, eliminating the possibility of rust. The heating element is symmetrically engineered for even heat distribution throughout the thermoplastic material.

This machine is used to process bleaching trays, sports mouthguards, implant splints, temporary splints, custom impression trays, denture bases, copings, temporary crowns and bridges and orthodontic appliances.

Features:

– Easy-to-use system

– Uses 5”x5” resin sheets

– Available in 110 Volt and 220 Volt

– Machine weight: 22 lbs.

– Machine size: 14 1/4″ x 8 1/2″ x 10″

– Symmetrical heating system

– Lightweight, rust-free aluminum frame

– Made in the U.S.A.

Please be aware: A Vacuum Former moulds the material by drawing (sucking) down the material over the model with a vacuum pump from the bottom. (Different to a more expensive Pressure Former technology, that push down material from top with high pressure compressed air to give superior adaption results)

- Manual heating and vacuum times. User must control and judge the process.

- Uses 127mm Square Thermoforming Material

- Typical Heating and Vacuum Time

- Preheat for 2-3 minute or to the Heating Coil turn an orange colour. (Traditional Vacuum forming machines use ceramic element that takes longer to heat than more modern Pressure formers that us more instant heat Infrared Heating elements)

- Visually check material as it heats to check how soft and saggy it is as it begins to heat.

- Depending On Material Thickness

- 1mm Thick - 1 min. 30 sec heat /10 to 15 sec. Vacuum / / 5-10 min cooling

- 4mm Mouthguard - 2 minutes Heat / 15 to 20 sec. Vacuum / 5-10 min cooling

- TIP: When using with Dual Laminate / Hard Soft Material – preheat fitting surface of material sheet before flipping the material and completing full heating cycle.

- Made In the U.S.A.

- 12 Month Warranty

Keystone / Proform Vacuum Former Machine III (3) AU 220V 7000332

- Brand: Keystone Industries

- Product Code: K-VFM3

The Machine III has been a staple in Keystone Industries’ long-lasting line of highly recommended vacuum former machines.

Watch Keystone video online – how to use machine. Search Youtube - Keystone Pro-Form Basic Forming - CLICK HERE

The Machine III has been a staple in Keystone Industries’ long-lasting line of highly recommended vacuum former machines. The price, features and reliability make it the first choice in dental vacuum formers. The machine has more power than any other dental vacuum former, which means the production of more accurate and defined dental thermoplastic appliance.

The aluminum construction is long-lasting, eliminating the possibility of rust. The heating element is symmetrically engineered for even heat distribution throughout the thermoplastic material.

This machine is used to process bleaching trays, sports mouthguards, implant splints, temporary splints, custom impression trays, denture bases, copings, temporary crowns and bridges and orthodontic appliances.

Features:

– Easy-to-use system

– Uses 5”x5” resin sheets

– Available in 110 Volt and 220 Volt

– Machine weight: 22 lbs.

– Machine size: 14 1/4″ x 8 1/2″ x 10″

– Symmetrical heating system

– Lightweight, rust-free aluminum frame

– Made in the U.S.A.

Please be aware: A Vacuum Former moulds the material by drawing (sucking) down the material over the model with a vacuum pump from the bottom. (Different to a more expensive Pressure Former technology, that push down material from top with high pressure compressed air to give superior adaption results)

- Manual heating and vacuum times. User must control and judge the process.

- Uses 127mm Square Thermoforming Material

- Typical Heating and Vacuum Time

- Preheat for 2-3 minute or to the Heating Coil turn an orange colour. (Traditional Vacuum forming machines use ceramic element that takes longer to heat than more modern Pressure formers that us more instant heat Infrared Heating elements)

- Visually check material as it heats to check how soft and saggy it is as it begins to heat.

- Depending On Material Thickness

- 1mm Thick - 1 min. 30 sec heat /10 to 15 sec. Vacuum / / 5-10 min cooling

- 4mm Mouthguard - 2 minutes Heat / 15 to 20 sec. Vacuum / 5-10 min cooling

- TIP: When using with Dual Laminate / Hard Soft Material – preheat fitting surface of material sheet before flipping the material and completing full heating cycle.

- Made In the U.S.A.

- 12 Month Warranty

Related Products

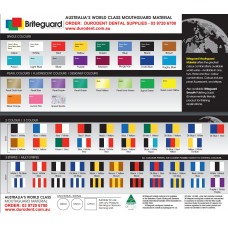

Briteguard Laminate / Bleaching Tray Material Soft 1.0mm - Pack Of 10

Multibuy Offers: BUY 5 Pack (50 sheets) - SAME TYPE - SAVE 10% Briteguard Clear Soft ..

Briteguard Laminate / Bleaching Tray Material Soft 2.0mm - Pack Of 10

Multibuy Offers: BUY 5 (50 sheets) - SAME TYPE - SAVE 10% Clear Soft EVA that is suitable for l..

Aldente RSB Dunaform PLUS Pressure Former 581-003-006 - V2 Upgraded

NEW Digital Model - 10 Program Memory Aldente DUNAFORM PLUS Pressure Former V2 RRP $..

Briteguard Mouthguard Material Colour Chart Tent Card - 1pc

Briteguard Mouthguard Material Colour Chart Tent Card - 1pc ..

Gibling Laminate / Bleaching Tray Material Soft 1.0mm - Pack Of 10

Multibuy Offers: BUY 5 Pack (50 sheets) - SAME TYPE - SAVE 10% Clear Soft EVA that is suitable ..

Durodent Supasolve 1L - Mouthguard Finishing Solvent

Durodent Supasolve 1L - Mouthguard Finishing Solvent Finishing solvent for smoothing ..

Aldente Ausblockwachs Thermoforming Blockout Wax - White - 110g - 581-004-011

Aldente Ausblockwachs Thermoforming Blockout Wax - White - 110g - 581-004-011 For blocking out un..