- Products

- Acrylics

- Heat Cure Acrylics

- AcrylX - Heatcure Acrylic

- AcrylX Xthetic HIGH IMPACT Heat Cure POWDER ONLY - Pink V (O2) Veined - 100g - SHORT DATE CLEARANCE

AcrylX Xthetic HIGH IMPACT Heat Cure POWDER ONLY - Pink V (O2) Veined - 100g - SHORT DATE CLEARANCE

- Brand: AcrylX

- Product Code: AX-HI-PV-100

AcrylX Xthetic HIGH IMPACT Heat Cure POWDER ONLY - Pink V (O2) Veined - 100g - SHORT DATE CLEARANCE

EXPIRY 03/2025 - 13 IN STOCK - SAVE 80%

Xthetic HIGH IMPACT Heat Cure – AcrylX Germany

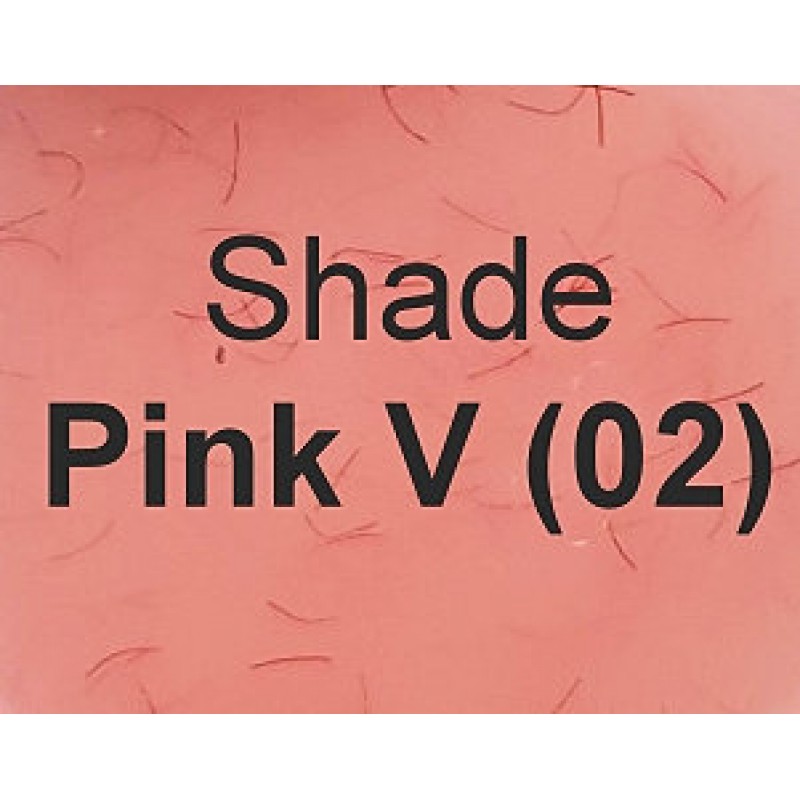

*Shade tab image is indicative only and may inaccurately show colour

High Impact Denture Base Resin, short heat cure cycle. Acrylic resin for the manufacture of removable or fixed dentures by using the packing and pressing technique as well as the injection technique.

Pink V (02) Veined – Great colour for high impact – Slightly darker pink veined works best with high impact acrylic.

Indications:

- Manufacture of total and partial dentures using the packing and pressing technique

- Manufacture of total and partial dentures using the injection technique

Product features:

- Very high impact strength

- Flexural strength 75Mpa

- Option of fast 20 minute cure rather than the long cure process if required

- High accuracy and high quality results guaranteed

- Excellent mechanical properties

- Optimal mucosal tolerance due to low residual monomer content

- Physiological shades and absolute color stability

- Cadmium free

- Evaluated and Cerrtified Biocompatibility

Mixing Ratio: 10g Powder : 4g-5g (4.25ml) Liquid

Processing times:

Swelling phase: approx. 10 min

Processing phase (packing / pressing): approx. 15 min

Processing phase (injection): approx. 5 min

Polymerisation:

This material can be polymerised successfully by:

Quick 20 Minute Cure Method (bring to boil 95°C + and polymerise for 20 minutes, rather than the normal 90 mins. Bench cool

or

Traditional High Impact Long Cure Method (Bring up to 70°C and hold for 60 mins, then increase to boiling point for 30 mins. Turn off and allow cooling for 20 mins. Bench cool) or.

If processing thick lowers or dentures with thick areas, as with all heat cure acrylics just make sure the temperature is brought up slower to 70°C for 30 - 60 minutes, then increase to boiling for 30 minutes to provided time for the whole flask to reach even temperature throughout and allow even polymerisation to reduce the chance of porosity occurring.

Of course the material can be processed by using any other hot-curing polymerization technique as well.

| Mechanical properties acc. to ISO 20795-1 | Requirements | Xthetic® high impact |

| Ultimate flexural strength in MPa | min. 65 | 75 |

| Flexural modulus in MPa | min. 2000 | 2300 |

| Maximum stress intensity factor in MPa | min. 1,9 | 2,3 |

| Total fracture work in J/m² | min. 900 | 1200 |

| Additional properties acc. to ISO 20795-1 | Requirements | Xthetic® high impact |

| Water absorption in μg/mm³ | max. 32 | 21 |

| Solubility in μg/mm³ | max. 1,6 | 0,3 |

| Residual monomer in % | max. 2,2 | 0,8 |

|

Other requirements |

Xthetic® high impact |

| DIN EN ISO 20795-1 Requirements concerning the packing plasticity | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the surface characteristics and the shape capability | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the color and the color stability | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the translucancy and the freedom from porosity | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the bonding to synthetic polymer teeth | fulfilled |

| DIN EN ISO 10993 Requirements concerning the biocompatibility | fulfilled |

AcrylX Xthetic HIGH IMPACT Heat Cure POWDER ONLY - Pink V (O2) Veined - 100g - SHORT DATE CLEARANCE

- Brand: AcrylX

- Product Code: AX-HI-PV-100

AcrylX Xthetic HIGH IMPACT Heat Cure POWDER ONLY - Pink V (O2) Veined - 100g - SHORT DATE CLEARANCE

EXPIRY 03/2025 - 13 IN STOCK - SAVE 80%

Xthetic HIGH IMPACT Heat Cure – AcrylX Germany

*Shade tab image is indicative only and may inaccurately show colour

High Impact Denture Base Resin, short heat cure cycle. Acrylic resin for the manufacture of removable or fixed dentures by using the packing and pressing technique as well as the injection technique.

Pink V (02) Veined – Great colour for high impact – Slightly darker pink veined works best with high impact acrylic.

Indications:

- Manufacture of total and partial dentures using the packing and pressing technique

- Manufacture of total and partial dentures using the injection technique

Product features:

- Very high impact strength

- Flexural strength 75Mpa

- Option of fast 20 minute cure rather than the long cure process if required

- High accuracy and high quality results guaranteed

- Excellent mechanical properties

- Optimal mucosal tolerance due to low residual monomer content

- Physiological shades and absolute color stability

- Cadmium free

- Evaluated and Cerrtified Biocompatibility

Mixing Ratio: 10g Powder : 4g-5g (4.25ml) Liquid

Processing times:

Swelling phase: approx. 10 min

Processing phase (packing / pressing): approx. 15 min

Processing phase (injection): approx. 5 min

Polymerisation:

This material can be polymerised successfully by:

Quick 20 Minute Cure Method (bring to boil 95°C + and polymerise for 20 minutes, rather than the normal 90 mins. Bench cool

or

Traditional High Impact Long Cure Method (Bring up to 70°C and hold for 60 mins, then increase to boiling point for 30 mins. Turn off and allow cooling for 20 mins. Bench cool) or.

If processing thick lowers or dentures with thick areas, as with all heat cure acrylics just make sure the temperature is brought up slower to 70°C for 30 - 60 minutes, then increase to boiling for 30 minutes to provided time for the whole flask to reach even temperature throughout and allow even polymerisation to reduce the chance of porosity occurring.

Of course the material can be processed by using any other hot-curing polymerization technique as well.

| Mechanical properties acc. to ISO 20795-1 | Requirements | Xthetic® high impact |

| Ultimate flexural strength in MPa | min. 65 | 75 |

| Flexural modulus in MPa | min. 2000 | 2300 |

| Maximum stress intensity factor in MPa | min. 1,9 | 2,3 |

| Total fracture work in J/m² | min. 900 | 1200 |

| Additional properties acc. to ISO 20795-1 | Requirements | Xthetic® high impact |

| Water absorption in μg/mm³ | max. 32 | 21 |

| Solubility in μg/mm³ | max. 1,6 | 0,3 |

| Residual monomer in % | max. 2,2 | 0,8 |

|

Other requirements |

Xthetic® high impact |

| DIN EN ISO 20795-1 Requirements concerning the packing plasticity | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the surface characteristics and the shape capability | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the color and the color stability | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the translucancy and the freedom from porosity | fulfilled |

| DIN EN ISO 20795-1 Requirements concerning the bonding to synthetic polymer teeth | fulfilled |

| DIN EN ISO 10993 Requirements concerning the biocompatibility | fulfilled |

Related Products

Kulzer Paladon 65 High Strength Heatcure Acrylic POWDER ONLY 1kg - Multiple Shades Available

Discounted Multibuy Powder and Liquid Packs Available - See Combo Product listed below in related pr..

AcrylX Xthetic HIGH IMPACT Heat Cure LIQUID ONLY 80ml - SHORT DATE CLEARANCE

AcrylX Xthetic HIGH IMPACT Heat Cure LIQUID ONLY 80ml - SHORT DATE CLEARANCE EXPIRY 07/2025 -..

AcrylX Xthetic HIGH IMPACT Heat Cure LIQUID ONLY 500ml

AcrylX Xthetic HIGH IMPACT Heat Cure LIQUID ONLY 500ml Xthetic HIGH IMPACT Heat Cure &n..

AcrylX Xthetic HIGH IMPACT Heat Cure POWDER ONLY - Pink V (O2) Veined - 1000g

AcrylX Xthetic HIGH IMPACT Heat Cure POWDER ONLY - Pink V (O2) Veined - 1000g INSTRUCTION..

AcrylX Xthetic HIGH IMPACT Heat Cure Powder & Liquid COMBO PACKS

AcrylX Xthetic HIGH IMPACT Heat Cure Powder & Liquid COMBO PACKS BULK - BUY OFFERS AVAILABLE ..